In part 1 of our cash strategist series we defined a business model and how cash is the life blood of a business. Part 2 examined income streams for the Food & Drink industry and how different marketing and route to market options produce a wide range of effects on your cash inflows.

Here in part 3 we look at how your business model choices impact the rate that cash leaves your business, focusing on the production aspect of your business.

Cash Outflows in Your Business Model

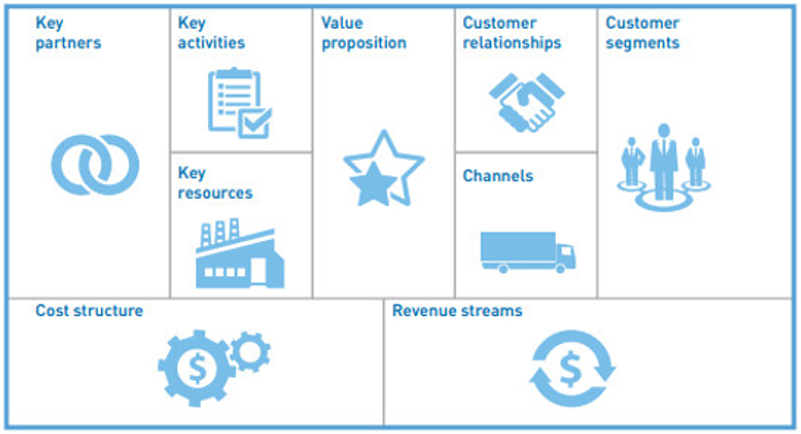

Cash outflows are shown on the left hand side of the business model canvas *

* Business Model Generation by Alexander Osterwalder & Yves Pigneur, 2010

Your key partners, activities and resources unite together to create your product. All have associated costs attached, and a variety of options are open to you.

However, even if all the options cost the same in terms of the £ value of cash leaving your bank account, the timing of the payments may vary hugely. This variation in cost structure could be the difference between you having cash or not, of you being a going concern or very concerned indeed.

Assuming that you have built sufficient scale and your kitchen table is no longer practical, there are two main routes to production – building your own facilities or outsourcing it to a production facility owned by a third party. We are going to explore the cash implications of both production routes.

Building your own Production Facility

Building your own facility, even on a small scale, requires upfront cash investment. You will need to lease, rent or buy a property and then fit it out with equipment – once you’ve bought the actual equipment itself. There are building and Health & Safety regulations to comply with. You will also have to get staff to run the facility. This means recruitment costs, salaries and training costs: all cause cash to leave your bank account before you have made any products to sell.

Having your own facility does come at a price. As well as the upfront investment, there are ongoing maintenance and running costs for both the building and the equipment.

You will need a staff team to run the facility. It requires management time to organise rotas and production shifts, plus you have to keep your staff engaged and motivated so they do not leave. This adds to the other key tasks of building the brand and driving sales which sit at the centre of your business. As this key task list grows, your ability to focus on each element shrinks: you run the risk of losing focus as you widen your responsibilities.

From a cash focus, the upfront costs are followed by regular outflows (eg payroll, rent, rates) and variable payments (ingredient purchases, maintenance bills) which fluctuate depending on timing of your production runs and purchasing agreements. Even if you produce nothing one week, there are still overheads to pay relating to your facility upkeep.

Yet there are substantial benefits of having your own facilities.

You have full control of your production process, which can be important for brand, quality and order fulfilment, amongst other reasons. You are also able to protect Intellectual Property more effectively with your own facility – e.g. special ingredients or processes remain secret to your business.

Having your own facility means you are able to experiment and innovate: the New Product Development (NPD) team has access to the facilities. The time to transform a new concept into a marketable proposition should be greatly reduced as your infrastructure is already in place, along with an experienced team.

Most businesses set up a facility with room for growth. This may be spare physical space, or the ability to add a double or triple shift in overnight and thereby maximise the productivity of your existing equipment.

However, (with luck) at some stage your sales demand will outgrow your facility’s capacity. When this happens, you will need to have another pile of cash available to invest in an additional or bigger production facility. By this stage you have an ongoing income stream from sales, and have a proven business track record, so raising the cash may be simpler than first time round: but you will still need a large amount of cash yet again.

Outsourcing to a Third Party Production Facility

Third party facilities are effectively factories which hire out their services to producers. Services are provided as a package deal, so you do not have to deal with sourcing workers, cleaners, maintenance staff etc – all costs to produce your product are included in a single unit price. As the facility also works with other producers, there are often efficiencies and economies of scale which can keep down costs per unit.

As such, with the physical and staffing infrastructure already in place and owned by another, there is usually no significant cash outlay when using outsourced facilities. The cash outflows are normally on a pay-as-you-go basis, varying in line with the volumes you order.

If you are just starting out with no credit history, you may have to pay the outsourcer in advance, prior to a production run commencing. The outsourcer is protecting their own business and doesn’t want to risk a bad debt. When you have an established (and good) relationship with the outsourcer, you should be negotiating your credit terms like with all suppliers (ie, paying the outsourcer 30 days after the production run). If you are able to pay a month after production, you reduce the cash tied up in your business and give yourself the freedom to invest it elsewhere in your business.

Scaling up your production output can be a lot easier with the right outsourced partner. It may be a case of increasing the number of production runs or assigning additional capacity within the existing facilities. This is significantly easier to do than building another facility. As you get real scale, then the outsourcer may need to invest in new production lines and buildings. Sometimes the outsourcer will ask you to contribute to these costs, if they are specific to your product needs, or they may set you a minimum order level over a period of time to ensure they recoup their costs. Either way, you are not having to front up the cash for a full facility.

Conversely, if your orders drop off for a period – which can happen for many reasons, from a sales decline, overstocking or a shortage of key ingredients – it is also simpler to downsize your production levels when outsourcing. The facility’s staff will simply move on to producing a different product for another business – they won’t be sitting around doing nothing, which is a risk if you own your own site.

Outsourcing also reduces the management burden on your internal team. The outsourcer is in charge of all staffing issues (including arranging operational rotas, staff management and payroll). They also have to comply with and pass Health & Safety and Food Safety audits. You will still need to work closely with your supplier to ensure the correct quality is achieved on a consistent basis: it is your brand that will suffer if inferior goods are sold.

Overall, outsourcing is a lower risk business model that demands less up-front cash, which is why most food start-ups outsource production in one form or other.

Picking the right outsourcer is absolutely central to your success, marrying together all of the left hand side of the business model canvas: Key partner, activity and facility all rolled into one.

Ideally, you and your outsourcer would share the same values, and you will feel that you can have a good personal relationship with them. This will be a long-term relationship, with inevitable sticky

points on both sides, so having a fundamental belief in your partnership will help both sides when working through the hard times.

However, in practice, you may have little choice in picking your outsourcer: there may only be one or two facilities in the country who can produce your goods and/ or package them.

If you’re choosing between two or three facilities, you will look at price: how much they are charging you per unit. This is a key factor, but price should not be viewed in isolation.

- For example, say you went with the outsourcer with the cheapest cost. Do you know why they are charging less?

- What if they skimped on quality requirements and a whole run was consigned to wastage?

- Or poor quality goods came into public hands and hit the media?

- What if they had erratic staff or a high staff turnover, causing production delays?

- What if the delays caused your short shelf-life ingredients to perish?

- What if there were logistics issues, delaying delivery? This would cause fulfilment shortages and possibly more wastage.

The list of potential problems can go on and on – but the above is probably enough to give you a flavour of what nightmares exist.

The reliability and quality of your chosen production facility is vital. Any shortcomings from your outsourcer will hit your pocket (cost of wastage, lost sales, shorting customer orders, brand reputational damage) far in excess of the £value you may have saved by choosing the producer with the lowest unit price.

You may or may not pay more per unit when using an outsourcer versus having your own facility. Even if you have the funds to build your own facility, both options are worth modelling out and examining.

Cash factors aside, outsourcing simplifies your business model enormously, and this will give you space to focus on building your business in the early days, even if you later build your own facility.

Once you’ve got a production facility sorted, you’ll soon find yourself the proud owner of some Stock.

Stock is the product you have made but not sold yet. Stock is a physical manifestation of Cash. You have paid out money to make your goods, but you have not sold them and converted them back into cash yet. For this reason, stock is trapped cash – cash effectively sitting in your warehouse rather than your bank account.

Your aim is to sell your stock of products as quickly as possible and get cash flowing into the business. You also need to aim to keep as little stock in reserve as possible, to minimise the amount of cash you have trapped in a warehouse.

In the food business, our products have a shelf life. If we are not able to sell our stock before that shelf life runs out, we are literally pouring money down the drain or into the bin when we dispose of that out of date stock.

Too much stock equals wastage or tied up cash; too little stock means shorting or losing customers.

So how do you know how much to produce?

This is where sales forecasting comes in, and from this you are able to plan your production requirements. Digging into your sales plan lets you understand when you are likely to make sales by product, the expected rate of sale and when a re-stock will be required. You can then translate this into a flexed production plan to minimise wastage and stock holdings.

Agreeing to large minimum order quantities (MOQs) with your supplier for a better price may backfire if you are not able to sell all the product before its shelf life expires.

Production and Stock building both require cash. This requirement will not go away as you get bigger and more established: instead, cash demands continually increase with business growth as you need to fund ever higher product volumes to meet sales demand. Yet with careful planning and detailed knowledge of both your income streams and operating costs, you can successfully manage and control this growth process.

In our fourth and final part of the cash strategist series, we examine a significant cash outflow (payroll), cash injections and how you actually manage your cash, regardless of your business model choices. Read part 4 here…